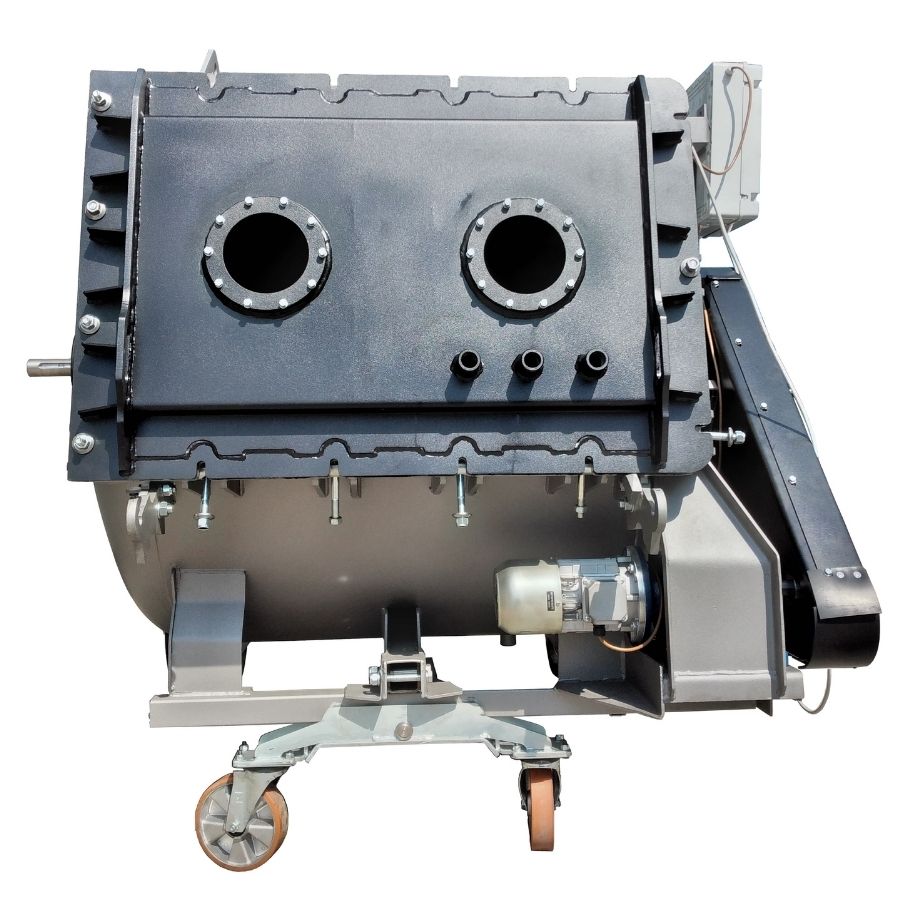

The relining drum is integrated with an impregnation roller conveyor and elements for moving the liner.

The distance between the two rollers is manually adjustable for impregnation during construction. The drum can also be used with pre-filled sock.

The internal electric rotation axis is ideal for winding the liner inside the drum. Adjustable speed for better control during relining operations. The discs on the internal sides are excellent for containing the sock.

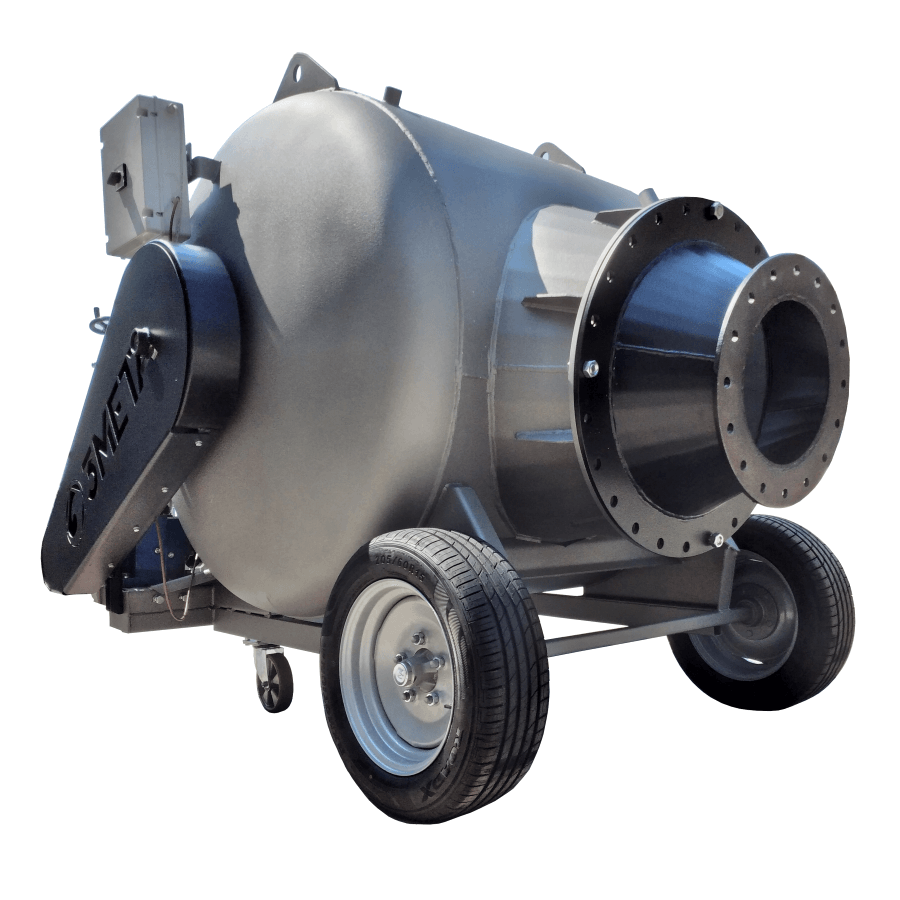

The movement of the Drum is facilitated by the steering wheels. Very useful to facilitate movement on site.

Extremely strong, in painted steel.

The drum dn 1500 for Relining is composed of the following essential parts:

1) Loading door of the filled Liner;

2) Winding axis;

3) Motor for moving the winding axis inside the machine;

4) Controls for the various movements;

5) Impregnation roller conveyor;

7) Wheels for handling.

Fittings at will:

Valves and coupling for air intake;

Valves and coupling for steam injection necessary for the catalysis of the resin present in the sheath;

Thermometer;

Security valves;

Pressure gauge

Applications

Drum for Relining pipes with sheaths impregnated with thermosetting resins.

Relining dn 1500 drum can be applied for different methods:

· With pneumatic thrust

· With UV lamp.

Use

The drum for Relining is brought close to the insertion in the pipeline to be restored and the following operations are performed:

1. Opening the door;

2 Locking of the sock between the rollers

2. Introduction of the resin inside the sock (possible use of pre-filled liner)

2. Liner insertion;

3. Winding facilitated by the rotation axis

4. Fixing the liner to the pipe;

5. Inversion of the liner inside the pipe to be restored (check in real time from the portholes that everything happens regularly);

6. Possible external boiler connection for steam polymerization;

7. Completion of operations with release from the flange

During use, the pressure and temperature gauges are monitored to ensure the set parameters. Any exceeding of these values triggers the safety valves.

The maintenance of the machine consists in cleaning it from any residues of the materials used inside the central box. The moving parts require periodic greasing

of the mechanisms involved. Check the efficiency of the safety valves every 6 months to ensure their safety.